Maximizing Efficiency in Material Handling with a Telescopic Radial Stacker

The telescopic radial stacker is revolutionizing the way businesses approach material handling. This specialty equipment is designed for the stacking and storage of bulk materials, providing versatility, efficiency, and enhanced productivity. Understanding how to utilize this powerful piece of machinery can lead to significant operational improvements in various industries, especially in the sectors of electronics and 3D printing.

Understanding Telescopic Radial Stackers

A telescopic radial stacker is a unique type of stacker that features a telescoping mechanism capable of extending and retracting its conveyor. This allows for the stacking of materials in a radial pattern, which is particularly beneficial in bulk material handling. The flexibility provided by the stacker’s radial movement enables operators to maximize the effective use of available space while minimizing the time needed for logistical operations.

Key Components of Telescopic Radial Stackers

- Telescopic Boom: The primary feature that allows for extended reach and height adjustments.

- Control Systems: Technologies that provide operators with easy management and precision control of stacking operations.

- Conveyor System: The conveyor belts enable smooth transport of materials to and from the stacker.

- Structural Frame: A robust and durable construction ensures stability and longevity under heavy use conditions.

The Advantages of Using a Telescopic Radial Stacker

Utilizing a telescopic radial stacker offers multiple advantages that can aid businesses in streamlining their operations:

1. Space Optimization

The ability to stack materials radially allows businesses to maximize their storage capabilities. In industries like electronics, where space can be at a premium, optimizing every inch can lead to drastically improved inventory management.

2. Flexibility in Stacking

With its adjustable reach, a telescopic radial stacker can be employed for various stacking tasks. This versatility enables businesses to adapt to changing requirements without needing multiple pieces of equipment.

3. Enhanced Efficiency

The speed and effectiveness of a telescopic radial stacker can significantly reduce the time spent on unloading and stacking materials. This boost in efficiency correlates directly with increased productivity and decreased operational costs.

4. Improved Safety Features

Modern telescopic radial stackers come equipped with safety features such as emergency stop systems and operator protection measures, reducing the risk of workplace accidents, which is a crucial aspect in high-intensity work environments.

Applications of Telescopic Radial Stackers

The versatility of the telescopic radial stacker allows it to be used across various industries. Here are some of the most notable applications:

Bulk Material Handling

In industries involving bulk materials, such as gravel, coal, and other aggregates, the need for effective storage solutions is paramount. Telescopic radial stackers enable the efficient temporary storage of materials, reducing the complexity of inventory management.

Electronics Manufacturing

In the electronics sector, precise stacking and retrieval of components are crucial. The adjustable reach and flexibility of the telescopic radial stacker allow manufacturers to handle and organize electronic components systematically.

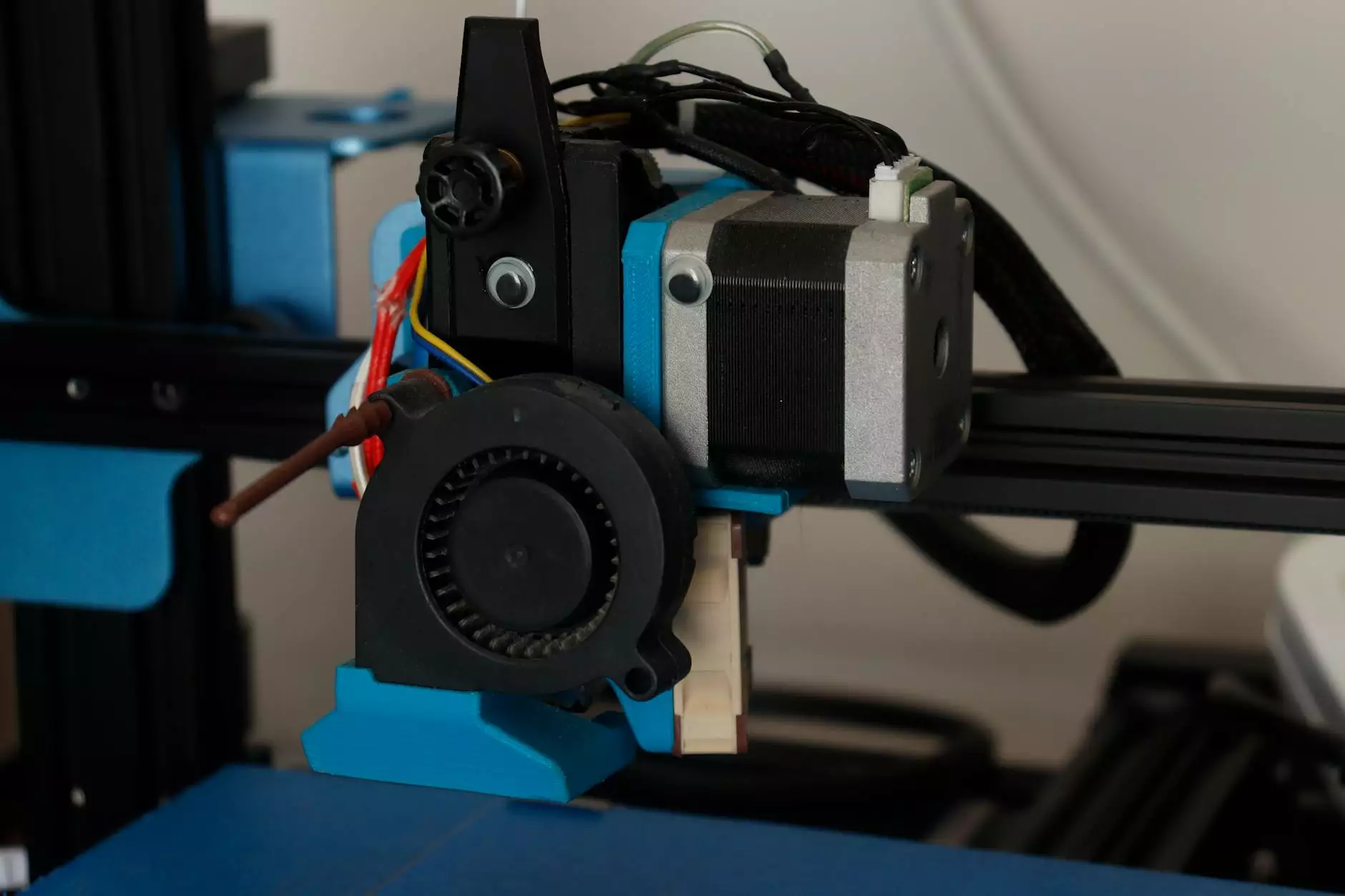

3D Printing Materials

The expansive market for 3D printing materials requires streamlined inventory solutions. Telescopic radial stackers can efficiently handle various filament types and other materials used in 3D printing processes, making it an invaluable asset for businesses in this field.

Choosing the Right Telescopic Radial Stacker

When considering a telescopic radial stacker, it is essential to evaluate the specific needs of your business:

1. Load Capacity

Assess the maximum load that the stacker will need to handle. Different models are designed for varying capacities, so ensuring you select the appropriate one is vital for operational efficiency.

2. Reach and Height

Consider the stacking height required in your facility. A telescopic radial stacker with adequate reach will enable optimal utilization of vertical space.

3. Mobility and Maneuverability

If your operations require movement within confined spaces, it is crucial to choose a model that offers excellent maneuverability. Examine the turning radius and overall dimensions of the stacker.

4. Control Options

Modern stackers often come with advanced control systems that allow for precision operation. Features such as remote control or automated stacking capabilities can enhance productivity.

Maintenance and Care for Your Telescopic Radial Stacker

Maintaining your telescopic radial stacker is essential for ensuring its longevity and reliability. Regular upkeep can prevent costly repairs and extend the lifespan of the machine.

1. Regular Inspections

Conduct frequent inspections to identify wear and tear before it becomes a severe issue. Check crucial components such as belts, bearings, and hydraulic systems.

2. Cleanliness

Keep the stacker clean, removing dirt and debris that may impact its operation. Regular cleaning will promote smoother functioning and decrease maintenance needs.

3. Lubrication

Ensure all moving parts are adequately lubricated to reduce friction and wear. Following the manufacturer’s guidelines for lubrication can greatly enhance performance.

4. Operator Training

Investing in comprehensive operator training ensures that the stacker is used correctly and safely. Trained personnel are better equipped to identify issues and operate the equipment efficiently.

Future Trends in Telescopic Radial Stackers

The industry is continuously evolving, and the future of telescopic radial stackers looks promising. Here are some trends to watch:

1. Automation and Robotics

As automation technology progresses, more advanced stackers with robotic features will become available, providing enhanced efficiency and safety.

2. Integration with IoT

The Internet of Things is set to revolutionize how equipment is monitored and managed. Future stackers may come equipped with IoT sensors that allow real-time tracking and predictive maintenance.

3. Sustainable Practices

With a growing focus on sustainability, manufacturers are designing more energy-efficient stackers that reduce operational costs while minimizing environmental impact.

Conclusion

In conclusion, a telescopic radial stacker represents a critical asset for companies looking to enhance their material handling operations. By investing in this cutting-edge equipment, businesses in industries such as electronics and 3D printing can streamline their processes, improve productivity, and achieve significant operational gains. As the industry continues to innovate, staying informed about emerging technologies and trends will keep your business at the forefront of efficiency and effectiveness.

For more information on optimizing your material handling processes and exploring the benefits of a telescopic radial stacker, visit polygonmach.com and discover the solutions tailored for your business needs.